China Professional Factory Standard Rubber O-ring Seal

- Only Rubber

- XIAMEN

- 60day

- 2500 tons per month

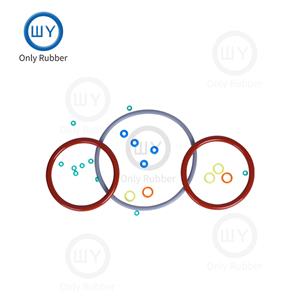

Color: As requirement

Material: Rubber Silicone FKM

Style: O Ring Mechanical Seal SEALING STRIP

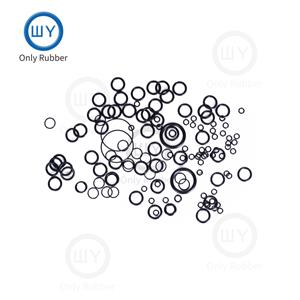

Customization: Size(Min. Order: 5000 Pieces)

Shipping: Support Express · Sea freight · Land freight · Air freight

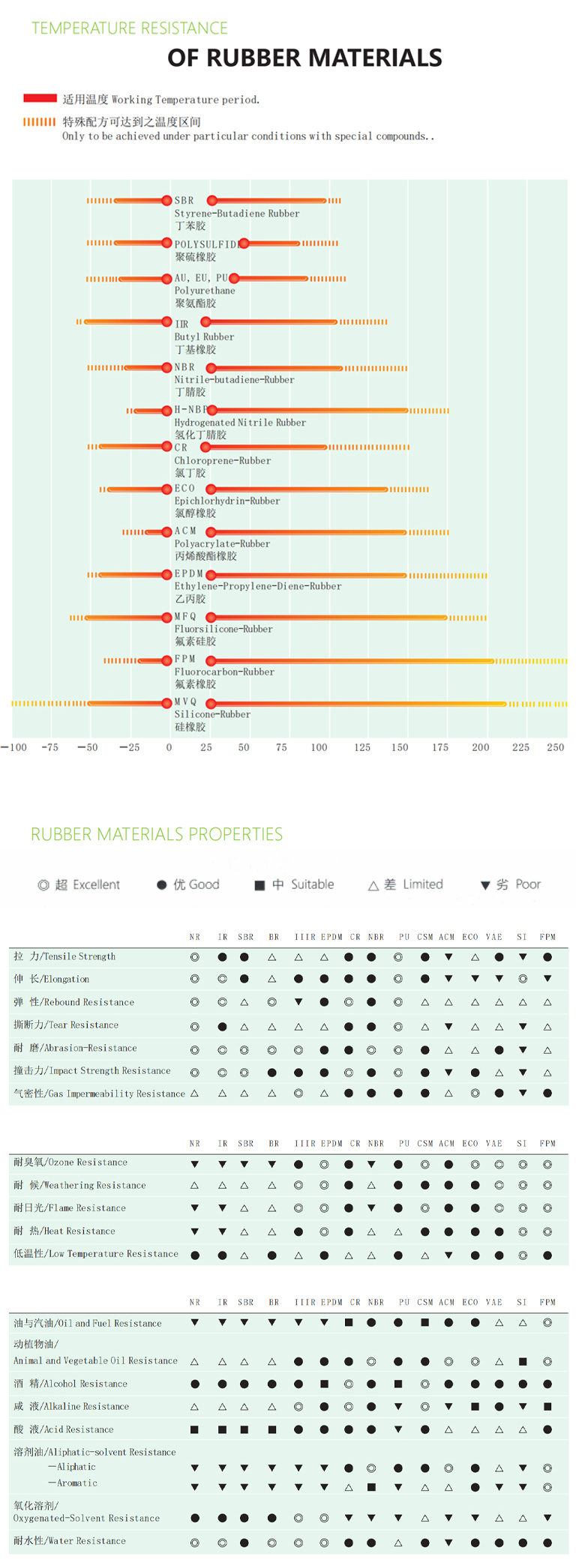

Ringsare available in the following elastomers:

NAME | CODE | ASTM D2000 CODE |

Nitrile Rubber | Buna-N/NBR | BF,BG,BK,CH |

Ethylene propylene Rubber | EPDM | AA,BA,CA,DA |

Silicone Rubber | VMQ SI | FC,FE,GE |

Hydrogenated Nitrile | HNBR | DH |

Polyacrylate Rubber | PA,ACM | DF,DH,EH |

Styrene-butadiene Rubber | SBR | AA |

Fluoro carbon Rubber | FPM,FKM,VITON | HK |

Fluorinated Silicone Rubber | FVMQ | FK |

Polychloroprene Rubber | CR | BS,SE |

Butyl Rubber | IIR | BA |

Natural Rubber | NR | AA |

Polyurethane Rubber | PU | BG |

Liquid Silicone Rubber | LSR | FC,FE,GE |

Product Info | |

Name | O-RINGS |

Material Type | NBR,EPDM,SILICONE,FKM,SBR,NR,etc. |

Hardness Range | 20-90 Shore A |

Color | Any color is OK |

Size | AS568, PG & Non-Standard O-Rings |

Tolerance Standard | AS568, ISO2768-M or ISO3302-1:2014 CLASS M2 |

Material Characteristic | See below rubber materials properties |

Application | For all industries |

Certificates | F D A, U L, NSF61, KTW, W270, ACS, AS4020, WRAS, EN681, EN549, ROHS, REACH, USP CLASS VI |

OEM / ODM | Available |

Packing Details | PE plastic bags then to the carton / as per your request |

Production Capacity & Lead Time | |

Production Capacity | 2500 tons per month |

Lead Time | 7 days for prototype tooling & samples, 14 days for production mold, 14-28 days for MOQ |

Shipping & Payment Terms | |

Port of Loading | XiaMen/other port as you want |

Shipping Method | SEA,AIR,DHL,UPS,FEDEX,TNT,ETC. |

Payment Terms | T/T, L/C, Paypal, Western Union |

Rubber Specification & Inspection Standard | |

Quality Acceptance Criteria | ISO2015/BSCI... According to customer's requirements |

O-Ring Tolerance Table:

ID/mm | Tolerance(±) | ID/mm | Tolerance(±) |

1.50 | 0.10 | 381.01-394.00 | 1.77 |

1.51-14.00 | 0.12 | 394.01-418.00 | 1.90 |

14.01-25.00 | 0.22 | 418.01-431.00 | 2.03 |

25.01-30.00 | 0.25 | 431.01-470.00 | 2.15 |

30.01-38.00 | 0.30 | 470.01-533.00 | 2.28 |

38.01-42.00 | 0.33 | 533.01-558.00 | 2.54 |

42.01-48.00 | 0.38 | 558.01-583.00 | 2.66 |

48.01-57.00 | 0.43 | 583.01-610.00 | 2.79 |

57.01-64.00 | 0.45 | 610.01-634.00 | 2.92 |

64.01-73.00 | 0.50 | 634.01-660.00 | 3.04 |

73.01-89.00 | 0.60 | 660.01-999.00 | 5.00 |

89.01-102.00 | 0.68 | CS/mm | Tolerance(±) |

102.01-105.00 | 0.71 | 2.00 | 0.07 |

105.01-125.00 | 0.76 | 2.01-3.00 | 0.07 |

125.01-153.00 | 0.88 | 3.01-4.00 | 0.10 |

153.01-178.00 | 1.01 | 4.01-5.00 | 0.12 |

178.01-203.00 | 1.41 | 5.01-7.00 | 0.15 |

203.01-230.00 | 1.27 | 7.01-10.00 | 0.20 |

230.01-267.00 | 1.39 | 10.01-15.00 | 0.25 |

267.01-330.00 | 1.52 | 15.01-25.00 | 0.35 |

330.01-381.00 | 1.65 | 25.01-100.00 | 0.45 |

Sealing Tolerance Table:

GB/T3672-2002

Idt ISO 3302-1:1996

Customized rubber tolerance grade:

A) M1 grade,for precision excellent quality Customized rubber

B) M2 grade,for excellent quality Customized rubber

C) M3 grade,for good quality Customized rubber

D) M4 grade,for suitable quality Customized rubber

Molded Rubber Tolerance Table:

| Nominal size | M1 | M2 | M3 | M4 | ||||

> | ≤ | F± | C± | F± | C± | F± | C± | F/C± |

0-4.0 | 0.08 | 0.10 | 0.10 | 0.15 | 0.25 | 0.40 | 0.50 | |

4.0-6.3 | 0.10 | 0.12 | 0.15 | 0.20 | 0.25 | 0.40 | 0.50 | |

6.3-10 | 0.10 | 0.15 | 0.20 | 0.20 | 0.35 | 0.50 | 0.70 | |

10-16 | 0.15 | 0.20 | 0.20 | 0.25 | 0.40 | 0.60 | 0.80 | |

16-25 | 0.20 | 0.20 | 0.25 | 0.35 | 0.50 | 0.80 | 1.00 | |

25-40 | 0.20 | 0.25 | 0.35 | 0.40 | 0.60 | 1.00 | 1.30 | |

40-63 | 0.25 | 0.35 | 0.40 | 0.50 | 0.80 | 1.30 | 1.60 | |

63-100 | 0.35 | 0.40 | 0.50 | 0.70 | 1.00 | 1.60 | 2.00 | |

100-160 | 0.4 | 0.50 | 0.70 | 0.80 | 1.30 | 2.00 | 2.50 | |

>160 | 0.3% | 0.4% | 0.5% | 0.7% | 0.8% | 1.3% | 1.3% | |

Remark:F stand for regular size which will change when mold move

C stand for width size which don’t change when mold move

Q1. What is the normal lead time for product orders?

A: Average lead times for prototype / first article are 1-2 weeks, if tooling is involved, lead time for production tooling is 10days, average production time after sample approval is 2-3 weeks.

Q2: How to check the quality of the bulk order?

A1: We provide preproduction samples before mass production for all customers if needed.

A2: We provide quality certs such as measurement report, material data sheet, COO, COA, etc. to all customers before delivery.

A3: We accept third party inspection such as S G S, TUV, INTERTEK, BV, etc.

Q3: Can you supply different color materials?

A: Yes, we can produce custom molded rubber and silicone rubber products in different colors, the color code will be required in case of an order.

Q4. What is your standard packing?

A: All the goods will be packed by carton box and loaded with pallets. Special packing method can be accepted when needed.

Q5. What's the payment term?

A: We accept T/T 30% deposit and 70% balance against copy of B/L or L/C at sight, West Union,VISA,Paypal is also accepted.